Therefore, the implementation of Six Sigma increases the earnings of the company. The high standard products have a good market, improving the business’s revenue generation. In addition, since the waste is reduced to many numbers, they are converted into sales, increasing the business’s revenue. Workers become more focused on daily improvement, making their work more impactful.

Advantages of Six Sigma

It is significant to note that for B2B customers, the Six Sigma standard for manufacturing products is a credible endorsement. You should also note that lean manufacturing is not particularly synonymous the average american’s charitable donations to Six Sigma. Adding tighter tolerances, better manufacturing equipment, improved testing systems and quality checks, eventually consumes more resources and increases manufacturing footprints.

Time to Say Goodbye to the “Air Gap”, a Manufacturing Digital Dinosaur

Since Six Sigma pertains to quality improvement and is a quality improvement process at its root, adoption of its protocols often leads to an increase in the overall costs. There are times when a company implements Six Sigma and there will be problems that arise as the company focuses on Six Sigma endorsed policies only and forgets about its specific mission statement or policies. For small business, it may also constrain new ideas favoring creativity and innovation, which requires some risk to implement. The Six Sigma methodology was developed in the mid-1980s by engineers at Motorola as a way to improve manufacturing processes. At its core, Six Sigma involves collecting and leveraging data to eliminate defects and waste in manufacturing, with the end goal of improving overall efficiency and quality.

The Roles & Responsibilities of A Quality Management Team

In addition, there are chances of increasing the time consumed to manufacture a product. Thus, either one of the factors has to be traded with the six sigma implementation in the manufacturing processes. Since Six Sigma helps reduce the defects and flaws in the products, the focus on failure reduces. The focus is then moving to strategy and development of the business processes rather than fixing the current problems. Therefore, complete focus can be on improvement and innovative ideas for product development. Moreover, Six Sigma plays an important part in developing processes depending on customer requirements.

What Is Lean Six Sigma? A Guide for Operational Excellence

- The various advantages and disadvantages of implementing Six Sigma processes in manufacturing are discussed here.

- That is because the cost savings made by virtue of eliminating returned products, costly reworks, and defective products, are only a process improvement byproduct.

- In the quest to refine processes and eliminate waste, Six Sigma may limit flexibility for unique circumstances, and leave less room for innovative new tools or methods.

- The motive behind the implementation of six sigma in General Electric was the realization of drawbacks in systems of the company by Jack Welch.

Lean and Six Sigma can contribute to the general improvement of any business process. Six Sigma’s heavy leaning toward quantitative methods can sometimes overshadow qualitative factors. For instance, while a process might be efficient numerically, it could be taking a toll on employee morale. Or, while defect rates might decrease, customer satisfaction might not necessarily increase proportionally. Six Sigma allows you to add value and ensure quality within your overall operation. Adding value and ensuring the quality of value is by far one of the most important components when attempting to differentiate yourself from the competition and get a step ahead.

What is Six Sigma Certification?

Six Sigma is a technique used to reduce the number of defects or errors in manufacturing. Implementing Six Sigma is to increase the quality of the products manufactured. The manufacturing industry has changed over the years with advancements in technology. Understanding the process and working towards quality improvement is the primary idea behind Six Sigma. Lean manufacturing is an additional concept that works in tandem with Six Sigma to decrease waste in the manufacturing process.

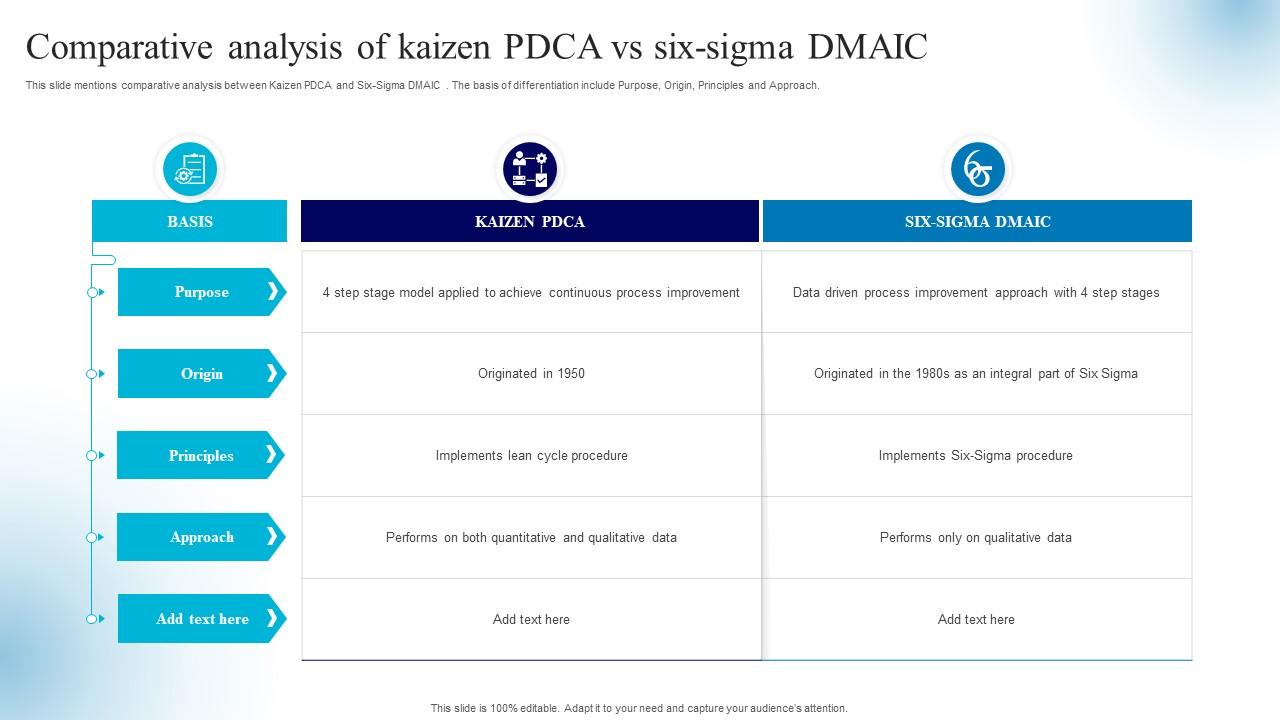

Next the team analyzes the process by isolating each input, or potential reason for any failures, and testing it as the possible root of the problem. The team measures the initial performance of the process, creating a benchmark, and pinpoints a list of inputs that may be hindering performance. A team of people, led by a Six Sigma expert, chooses a process to focus on and defines the problem it wishes to solve. The five phases of the Six Sigma method, known as DMAIC, are defining, measuring, analyzing, improving, and controlling.

With its data-driven methodology, Six Sigma focuses on eliminating defects and ensuring process improvements. Six Sigma pertains to the data approach utilized by companies to upgrade business processes. The method utilizes a five-stop methodology to eliminate defects at all stages within a company. Six Sigma defines defects as anything that is not within customer expectations and that is considered wasteful within a manufacturing operation. Implementing Six Sigma leads to a significant improvement in the quality of products and services. Organisations can consistently meet or exceed customer expectations by identifying and eliminating defects.

He was of the opinion that the company needs a complete overhaul to eliminate its waste build-up and to cope up with the poor governance issues. It’s essential to understand that while Six Sigma can provide tools and methods for improvement, its success largely depends on its correct implementation and the organization’s commitment to continuous improvement. While Six Sigma offers a structured approach to improving processes and eliminating defects, it’s not a one-size-fits-all solution.

Unfortunately, however, you may end up losing out to your cheaper competitors, especially if you are dealing in products that customers do not actually care about extra quality. Since Six Sigma heavily relies on data, you can conveniently and comfortably look into your processes in real time. As the measurement trend starts hitting the lower of upper chart control limits, you’ll be able to identify the problem and swiftly act accordingly after understanding, documenting and measuring the current process. In case the revised process fails to deliver as required, your Six Sigma team will be on standby to evaluate it, and subsequently, correct any developing problems. Six Sigma is a rigorous and complex methodology that requires a deep understanding of statistical analysis and problem-solving techniques. This complexity can make adopting and implementing it is challenging for organisations without proper training and support.